Search this site

More Info

Latest News & Articles

New! Stocked Adhesive Materials; Ship in Five Business Days

New! Stocked Adhesive Materials; Ship in Five Business Days

Appli-Tec now offers stocked parts for our most frequently ordered adhesive formulations.

Appli-Thane 7800 & 7810 Ideal for Dam and Fill Applications

Appli-Thane 7800 & 7810 Ideal for Dam and Fill Applications

To encapsulate a small section or component of a circuit board, a process called “dam and fill” can be used.

Introducing 1.0 W/mK 5340 Two-Part Thermally Conductive Epoxy in 1:1 Cartridges

Introducing 1.0 W/mK 5340 Two-Part Thermally Conductive Epoxy in 1:1 Cartridges

New 5340 Epoxy – Conveniently packaged in 1:1 dual cartridges for easy mixing.

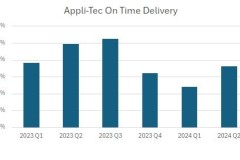

Appli-Tec Achieves Greater than 98% On-Time Delivery

Appli-Tec Achieves Greater than 98% On-Time Delivery

Appli-Tec improved several metrics, including 80% or more of shelf-life remaining for products shipped, shorter lead times, and OTD.

Appli-Tec Introduces 5390 Epoxy with Verified 4.3 W/mK

Appli-Tec Introduces 5390 Epoxy with Verified 4.3 W/mK

Appli-Tec’s 5390 Epoxy is very thermally conductive, electrically insulative, and silver-free.

FAQ: “I Have a Difficult Adhesive Mix Ratio. Can Appli-Tec Help?”

FAQ: “I Have a Difficult Adhesive Mix Ratio. Can Appli-Tec Help?”

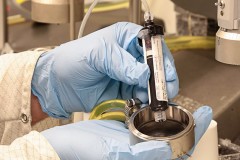

The impact of mix ratio on adhesive performance is critical and impacts everything from cure rate to outgassing properties.

How Temperature and Humidity Affect Your Adhesive Mix

How Temperature and Humidity Affect Your Adhesive Mix

Temperature and humidity greatly affect viscosity, pot life, adhesive performance, and cured properties.

Appli-Tec Celebrates 40th Year – and a Business Transformation

Appli-Tec Celebrates 40th Year – and a Business Transformation

CEO Tim Walsh’s thoughts on Appli-Tec’s 40th anniversary — and how the company has transformed over the last three years.

The Case for 100% Traceability of Adhesive Materials

The Case for 100% Traceability of Adhesive Materials

Appli-Tec has had 100% traceability for decades. If you’re ever audited, we can tell you who did what, when, where, and how.

Appl-Tec Reduced Trash, Improved Recycling and Composting

Appl-Tec Reduced Trash, Improved Recycling and Composting

How the Appli-Tec team reduced the amount of trash by 90%.

Room Temperature Cure vs. Oven Cure for Adhesives

Room Temperature Cure vs. Oven Cure for Adhesives

The type of adhesive cure to use depends on your application, what you’re trying to achieve, and your time frame.

95% of our product line is solvent-free – meaning the materials aren’t flammable or have very low VOC emission.