Search this site

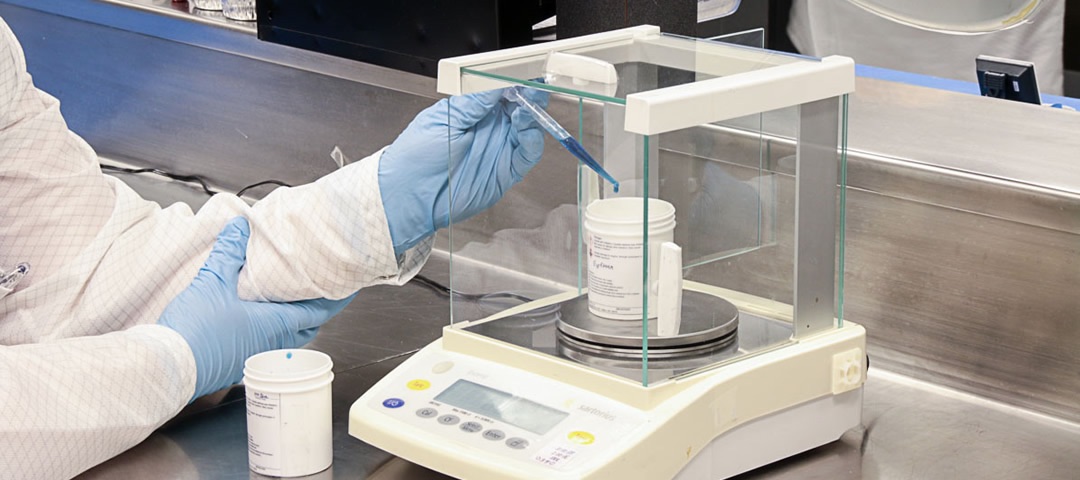

Custom Material Development

No matter your application criteria, Appli-Tec can develop a formulation to suit your needs.

When solutions aren’t readily available, Appli-Tec can develop and specify new materials, or modify a formulation, to meet the precise demands of your new or existing application.

Custom formulations can conform to structural, thermal, electrical, rheological and acoustical specifications.

Our product line includes UV-curable and multi-component epoxies, acrylates, polyurethanes, polysulfides and silicones.

Examples of typical customizations include:

- Addition of fumed silica (CAB-O-SIL) for better thixotropic properties

- Increasing or decreasing density as well as enhancement of thermal and electrical properties

- Adjustments of pot-life and/or cure time and cure temperature

- Addition of UV tracer

- Color modifications

Relying upon extensive academic and industry experience in material and process development, Appli-Tec satisfies the highest standards for excellence in design, development and service.

We strive to exceed the most demanding requirements of aerospace, defense, and industrial applications.

New Applications

I want to discuss my application challenges, order samples, or place a first-time order.

Existing Applications

I need to reorder an existing part number, I have a BOM/Spec.