Search this site

More Info

Advances in Pre-Mixed and Frozen Adhesives – Appli-Tec Continues to Innovate

Advances in Pre-Mixed and Frozen Adhesives – Appli-Tec Continues to Innovate

With continued innovations, Appli-Tec can “weather” a two-week power outage — ensuring on-time delivery of PMF adhesive materials.

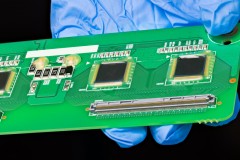

Tech Tip: Bonding Small Electronics to Printed Circuit Boards

Tech Tip: Bonding Small Electronics to Printed Circuit Boards

Learn why bonding components to PCBs is different than metal-to-metal bonding (e.g. aluminum to aluminum).

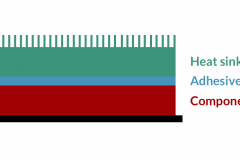

Three Benefits of Thermally Conductive Adhesives for High Reliability Heat Sink Applications

Three Benefits of Thermally Conductive Adhesives for High Reliability Heat Sink Applications

Appli-Tec thermally conductive adhesives eliminate the three challenges associated with thermal grease and pads for heat sink applications.

Bonding – Staking – Potting – Encapsulation:

Bonding – Staking – Potting – Encapsulation: Choosing the Right Adhesive for Your Application

The key difference between potting and encapsulation explained.

Choosing Thermally Conductive Adhesives for Heat Sink Applications

Choosing Thermally Conductive Adhesives for Heat Sink Applications

Solve challenges with heat sink applications that thermal conductive pads can’t handle.

Appli-Thane® 7300: First Adhesive Material to Deliver Best-in-Class Thermal Conductivity

Appli-Thane® 7300: First Adhesive Material to Deliver Best-in-Class Thermal Conductivity

Launched in 2012, Appli-Thane® 7300 has become our most requested product.

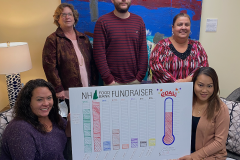

Appli-Tec Employees Raise $2,118 for NH Food Bank

Appli-Tec Employees Raise $2,118 for NH Food Bank

As part of our People, Planet, Prosperity vision, we held an internal food drive fundraiser.

FAQ: What is the Value of Appli-Tec’s PMF Adhesives?

FAQ: What is the Value of Appli-Tec’s PMF Adhesives?

At Appli-Tec, we test all adhesives to meet our own internal specifications – as well as to customer-supplied specs.

Appli-Tec Part of NASA Goddard Webb Space Telescope Project

Appli-Tec Part of NASA Goddard Webb Space Telescope Project

One of the most complex spacecraft ever made, NASA’s James Webb Space Telescope will allow scientists to break new ground.

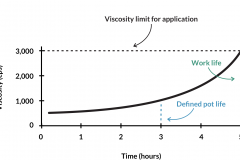

Maintaining Adhesive Viscosity and Work Life

Maintaining Adhesive Viscosity and Work Life

Work life and pot life can vary greatly depending on the adhesive material, its packaging (e.g. frozen, two-part kit), and the application.

What’s Appli-Tec’s procedure for testing lap shear?

What’s Appli-Tec’s procedure for testing lap shear?

Testing an adhesive’s lap shear is important because it allows for a strength comparison between different adhesive materials on a known substrate.

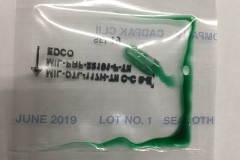

Shipping Indicator Tube

Shipping Indicator Tube

How to read the Appli-Tec Shipping Indicator Tube that arrives with every shipment of our PMF adhesives.