Search this site

Bonding – Staking – Potting – Encapsulation:

Choosing the Right Adhesive for Your Application

Appli-Tec adhesive materials are used in hundreds of applications, from aerospace projects – such as NASA’s James Webb Space Telescope and satellite communications – to medical devices and industrial applications.

While we work closely with engineers to recommend or customize an adhesive formulation for their specialized application, our main requests regard adhesives for bonding, staking, potting, and encapsulation.

Bonding

Bonding is a general term that denotes the chemical joining or bond between two substrates.

While this definition sounds straightforward, a good chemical bond depends on many factors, including:

- The adhesive’s chemical and physical characteristics

- The substrates being bonded

- Proper surface preparation for wetting

- Cure temperature with the optimized cure time

Appli-Tec offers over 20 adhesive materials suitable for bonding applications, including urethanes, epoxies, and poly sulfides. Whether you need to high thermal conductivity with low outgassing properties or long pot life, we have a material to suit your bonding needs.

Related Tech Tip: Bonding Small Electronics to Printed Circuit Boards

Staking

Staking is the process of applying an adhesive to strategically support component leads during vibration and shock exposure. (Engineers sometimes refer to this process as “tacking.”) Aerospace applications often require staking because of thermal cycling.

We offer 14 different materials suitable for staking applications, including low outgas urethanes and epoxies that are thermally conductive or insulative.

Related Tech Tip: Polyurethane Adhesives Absorb Stress for Aerospace Applications

Potting & Encapsulation

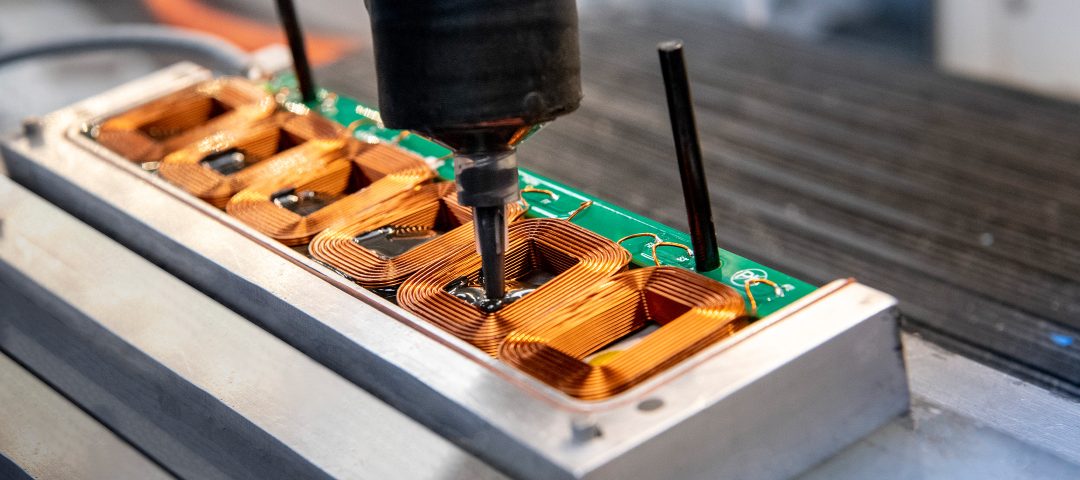

Potting and encapsulation serve to protect sensitive components or assemblies from environmental exposure. Adhesives used for potting or encapsulation can also offer thermal conductivity to remove heat, provide electrical insulation, and protect against shock and vibration.

Often used interchangeably, potting and encapsulation are similar processes but differ in one key way.

A potted part often has a housing that holds the assembly and the potting adhesive – the adhesive is in the final part.

Appli-Tec offers high-performance potting compounds specifically designed for potting, staking, and encapsulating electronics, power supplies, coils, and transformers.

Encapsulation often doesn’t involve a housing or external container for the adhesive.

Circuit board being encapsulated.

Appli-Tec offers 10 adhesive materials designed for potting. We also offer seven materials suitable for encapsulation applications.

“Off-the-shelf” adhesive materials + hundreds of others

If you don’t see what you need on our Adhesive Materials & TDS page, please inquire!

We take great pride in helping you choose the correct adhesive material for your application.

We can work closely with you to test materials in our lab or help you analyze your own in-house results. We can also recommend replacement adhesives for materials that have been discontinued.

In addition to the “off-the-shelf” materials listed on our Materials & TDS page, Appli-Tec offers a variety of other adhesives for specialty applications. We can also custom formulate a material for your application.

New Applications

I want to discuss my application challenges, order samples, or place a first-time order.

Existing Applications

I need to reorder an existing part number, I have a BOM/Spec.