Search this site

Work life and pot life are often used interchangeably when discussing adhesives. These properties, however, can vary greatly depending on the adhesive material, its packaging (e.g. frozen, two-part kit), and the application.

For pre-mixed and frozen (PMF) adhesives, work life is highly dependent on having a controlled thaw process.

Pot life

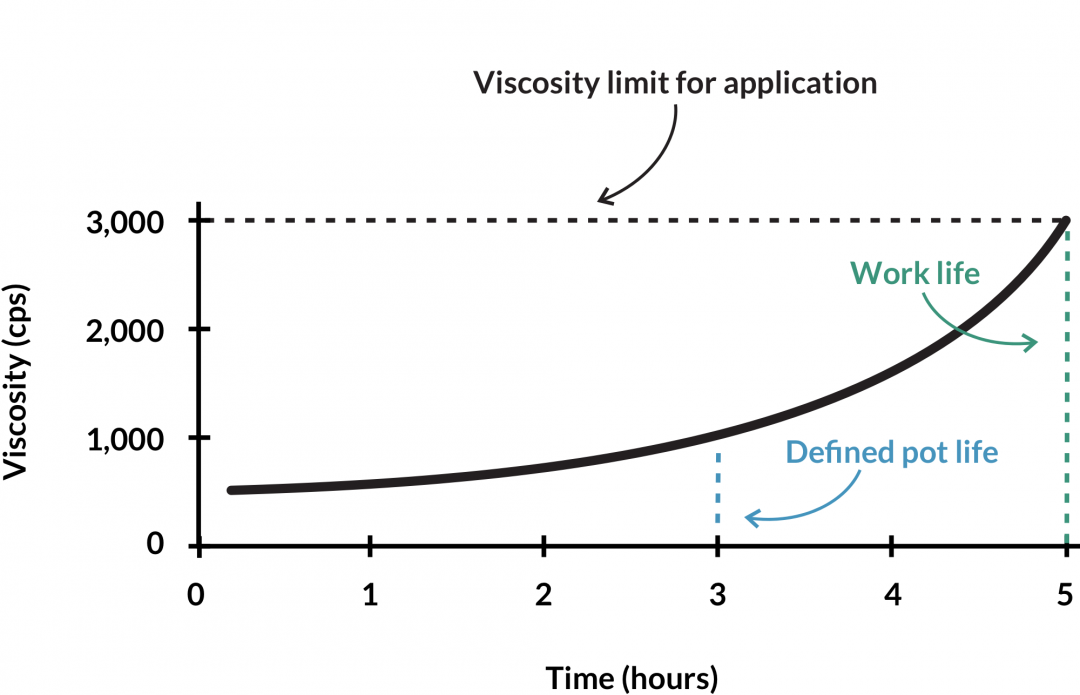

Pot life refers to the amount of time required for a material to reach double its initial viscosity. Timing for pot life begins when the frozen material reaches approximately 18°C or ambient conditions.

Pot life is a number generated in the lab and is included on technical data sheets (TDS) to help engineers compare adhesive reaction rates.

Work life

Work life refers to the amount of time a thawed material retains the correct viscosity for it to be properly applied to a part or substrate.

Work life can be shorter or longer than the pot life and is application-specific. For example, if an application can tolerate a viscosity higher than double the initial viscosity, then the work life for the adhesive for that application will be longer than the pot life.

Work life is also dependent on the cure type (room temperature or heat) and the application. Appli-Tec’s Appli-Thane® 7308, for example, can be used for over eight hours for automated dispensing. The material can be cured during mass-reflow without disturbing the placement of components – eliminating several costly component level processing steps. It also eliminates the need for a separate cure cycle.

Many of our other long work life materials are cured at elevated temperatures.

Materials with room temperature cures, such as our 5200 Epoxy, have a much shorter work life – anywhere from 30 minutes to 1 hour.

Controlling viscosity when thawing frozen adhesives

Appli-Tec creates frozen material by first mixing the resin and hardener together then flash freezing it, which stops the chemical reaction.

Appli-Thane aerospace grade adhesives are precision mixed, degassed and frozen (Cryo-Pac®) and comply with Appli-Tec’s rigorous testing and traceability standards.

As we explained in our Shelf Life Considerations FAQ, the reaction of an adhesive increases as the temperature increases.

You have to start with a controlled process to thaw your frozen adhesives to ensure the proper performance of your adhesive system.

- Location – Because room temperatures can vary, thaw syringes in the same room, and preferably in the same place, to avoid hot or cold spots.

- Temperature – Ensure the room you’ve chosen has a consistent temperature. For example, some rooms can be hot one day and cold the next. Be aware of the location of HVAC vents or fans as these can increase airflow on thawing syringes – and thus speed up the material’s thaw and potentially its viscosity.

- Position – Place the syringe vertically, with the tip pointing up. This will allow air bubbles in the syringe to accumulate in the tip of the syringe, which makes the air easy to bleed out before attaching a needle.

- Syringe handling – Do not thaw syringes by rolling them back and forth in your hands. Doing this can create “freeze-thaw voids” or gaps between the adhesive and the inside wall of the syringe due to the plastic expanding as it thaws.

- Time your thaw – We recommend that you consistently use a timer when thawing material and making note of thaw times by syringe size and material type.

- Remove condensation – Before using the thawed material, always gently wipe each syringe to remove any condensation in order to keep it from dripping into your application.

By creating a written process for thawing adhesive material, and following it consistently, you’ll ensure your material has the correct viscosity – from the start of your application to its completion.

Learn more about our defect-free PMF adhesives

New Applications

I want to discuss my application challenges, order samples, or place a first-time order.

Existing Applications

I need to reorder an existing part number, I have a BOM/Spec.