Search this site

Despite its frozen state, a pre-mixed adhesive material is still reacting. Freezing will slow down the reaction time to months or even years, but it doesn’t completely stop it. Unlike frozen hamburger, which thaws over a few hours, frozen adhesives begin to thaw – and thus react – immediately when exposed to warmer temperatures. It’s this reaction that affects the viscosity of the material. As the reaction proceeds, the viscosity increases. When the freezer is opened, warm air is introduced to the environment. The freezer then recalibrates. Open the door too frequently and the freezer is unable to consistently maintain its setting (e.g. -40°C or below). When searching for adhesive syringes needed for a project or job, customers will pull packages of syringes out of the freezer and set them on top. It doesn’t take long for the material to begin to thaw – and condensation to form on the syringes. A 3cc syringe, for example, will thaw in 10 to 15 minutes at 67 to 68 degrees Fahrenheit. Even a few minutes outside the freezer will speed up the reaction time. Once the correct material is located, the syringes with the now reacting material are put back in the freezer. The formed condensation obscures the label – making it more difficult to read and requiring longer time to locate the correct material as time goes on. A warm running freezer is usually due to a faulty compressor or condenser. Even a few degrees change in temperature can affect the viscosity of the adhesive. Similar to your at-home freezer, if your facility loses power for several minutes or hours, the frozen adhesives will begin to thaw – even if you don’t open the freezer. Make sure everyone understands how temperature changes affect frozen material. You can also add a “stop” sign to the freezer so that people don’t pull out bags of syringes while searching for another material. In response to customer requests, Appli-Tec began color-coding labels several years ago. The color stripe allows you to quickly ID a product in the freezer without having to pull out bags in order to read the labels. This process is best overseen by a company specializing in biotechnology, pharma, and medical device freezer calibration. For additional information about storing and thawing your Appli-Tec pre-mixed and frozen adhesive syringes and cartridges, see our Material Handling Tips. I want to discuss my application challenges, order samples, or place a first-time order. I need to reorder an existing part number, I have a BOM/Spec.

My Adhesive Material Seems Thicker Than Normal. What’s the Problem?

Factors that affect your adhesive before it’s used:

Opening the freezer frequently

Pulling adhesive packages out of the freezer

Freezer is running warm

Power failure

Tips for correctly storing your pre-mixed and frozen adhesives

Educate your team

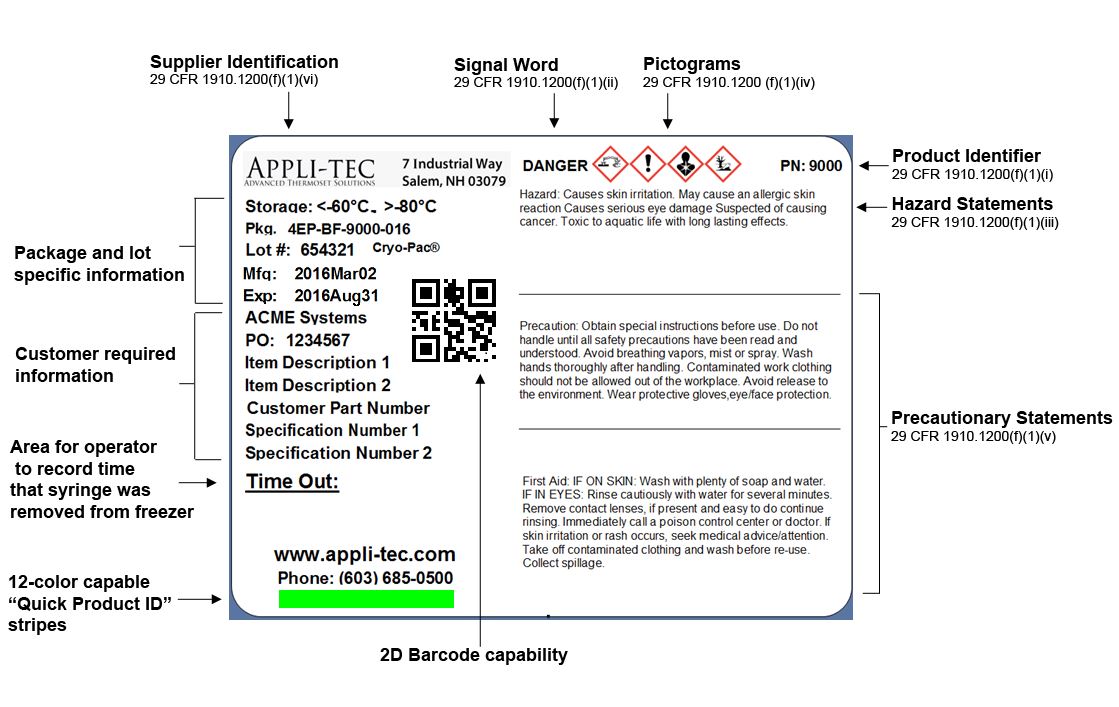

Add a color code to syringe labels

Ensure your freezer is correctly calibrated

Learn more

New Applications

Existing Applications