Search this site

Meticulously processed to exact specifications, Appli-Tec’s PMF adhesives guarantee consistent results.

Why PMF Adhesives?

Many of the adhesives used in aerospace applications are two-component systems. The problem, however, is that weighing and mixing components together in-house often leads to weighing errors or under-mixing, contamination, time-consuming and expensive rework, and scheduling delays.

Worse yet, undiscovered problems can affect these adhesives, as well as critical hardware, in space, where repair isn’t feasible and failure is not an option.

For these reasons and more, engineers turn to Appli-Tec.

Appli-Tec specializes in the production of PMF multi-component materials including epoxy, silicone, polyurethane and polysulfide.

Meticulously processed to exact specifications, Appli-Tec’s precision mixed and frozen (PMF) adhesives guarantee consistent results. Rigorous testing ensures every batch of material performs the same.

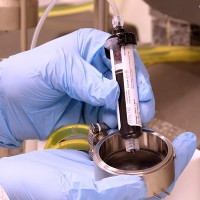

To obtain the PMF adhesive, Appli-Tec mixes the Part A (resin) and the Part B (hardener) of an adhesive system. We then degas (or remove the air from the mixture), and freeze the material to <-40°C.

The product is shipped under dry ice to maintain the <-40°C temperature. By storing the material at less than <-40°C, the reaction is stopped for months – up to one year.

When ready to use, customers simply remove a syringe from the freezer, wait 10 – 30 minutes (depending on syringe size) for the syringe to thaw, then use. The material is as good as if it were mixed minutes prior.

When you switch to Appli-Tec PMF adhesives, you’re assured of zero mixing errors, reduced risk, and peace of mind. No other frozen adhesive supplier matches our expertise and attention to detail.

Why you should consider Appli-Tec’s PMF adhesives

Our mixing process

Our mixing process

Our state of the art, highly refined, well-documented process will assure the highest quality.

Highlights:

- Highly trained technicians

- State of the art mixing equipment

- Vacuum degassing

- Nitrogen purging

- Cryogenic freezing

Your need for performance

Your need for performance

- Thermally conductive

- Electrically conductive

- Tough, non brittle or flexible

- High strength

- Low outgassing

- Environmental protection

- Free flowing - wicking

Repeatable results

Repeatable results

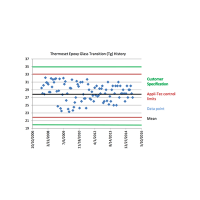

- FTIR validation of every chemical

- Confirming material properties

- Glass transition temperature

- Lap shear strength

- Shore hardness

- Viscosity and/or application rate

- Particle size

Custom packaging

Custom packaging

- Packaged for your application

- 1cc to 20oz cartridges

- Pneumatic or manual dispense

- 2D barcoding

- Color coding available

- GHS compliant labels

Appli-Tec will custom package PMF adhesives to suit your application.

Maximum shelf life

Maximum shelf life

- Nitrogen purged processing

- Less than -40° flash freezing

- Extends storage life

- Eliminates settling

- Packaged in vapor barrier bags

- Environmentally protected

Worldwide delivery

Worldwide delivery

- Indicator tubes confirms your shipment

- Dry ice filled for up to 120 hrs. of transit

- Emergency expedites are available

- Current SDS included with shipment

- Vapor barrier bags protects the adhesive

New Applications

I want to discuss my application challenges, order samples, or place a first-time order.

Existing Applications

I need to reorder an existing part number, I have a BOM/Spec.