Search this site

We often receive drawings or other information where the adhesive specification information is missing, or the wrong info is included.

We’ve created this how-to article to help you create an adhesive specification. To use it, download the interactive PDF worksheet and complete it using the information on this page. (The numbered sections on the worksheet correspond to the numbered sections here.)

Then, save the PDF worksheet with your answers and send it to us. Thank you!

Tips for Writing a Simplified Specification for a Precision Mixed Degassed and Frozen Adhesive

1) Scope

Define what you need.

For example: This specification defines the requirements of a precision mixed, frozen, degassed epoxy that is low outgassing, thermally conductive, electrically insulating and stable at service temperatures from -60 to 110°C.

2) External Specifications (related to adhesive or testing requirements)

Refer to properties of the adhesive and are related to adhesive properties or testing requirements. If your adhesive is required to meet a specification or must be tested to a standard, please include the Standard name and revision level: e.g MIL, ASTM, ANSI/ASQC, SAE type specifications.

3) Properties of uncured raw materials

These will usually come from the manufacturer of the raw material. Look for the ranges tested to on their C of A: never rely on a technical data sheet or require one data point instead of a range. List any critical properties of raw materials such as densities or particle size requirements if it will influence the end use properties of the mixed adhesive.

| Property | Test Method | Part A (Mfg + Tradename) | Part B (Mfg + Tradename) |

|---|---|---|---|

| Density* | ASTM *** | 2.13-2.38 | 0.95 – 0.98 |

| Color | ASTM *** | < 50 | 10 – 30 |

| Shelf Life (Time @ Temp) | 6 Mo @ 23°C | 12 Mo @ 23°C |

* If something is only a typical value and not a requirement state that.

4) Mix Ratios

Mix ratios always should have a tolerance of accuracy. Tolerances are usually +/- 1.0%.

| Material (Mfg + Tradename) | Parts by Weight |

|---|---|

| A | 40.0 +/-0.4 |

| B | 50.0 +/- 0.5 |

| C | 10.0 +/- 0.1 |

5) Cure Schedule

The cure schedule should represent what you do in your process. Make sure your cure will be complete and there is no residual energy left or your final cured properties will change over time. Appli-Tec runs a standard glass transition temperature( Tg) test on every lot of material and can use this information to check the cure temperature and time is adequate. If your process has a long cure (e.g. 7 days @ RT) consider a faster cure for conformance testing (lot to lot basis); this way if you need to expedite an order you will not have to wait to validate its cured properties.

| Cure Temperature (+/- 5°C) | Cure Time (Hrs) | Qualification | Conformance |

|---|---|---|---|

| 23 | 168 | X | |

| 150 | 1 | X | X |

6) Final properties of the PMF adhesive

Break this into uncured and cured properties. Clearly state tests that are required to qualify the adhesive (Qualification tests) and the tests needed on a lot to lot basis (Conformance tests). Be sure to specify the cure to use.

| Uncured Properties | ||||

|---|---|---|---|---|

| Property (Units) @ Condition | Test Method | Requirement | Qualification | Conformance |

| Viscosity (CPS) | ASTM *** | 1000 -3000 | X | X |

| Cured Properties | ||||

| Property (Units) @ Condition | Test Method | Requirement | Qualification | Conformance |

| Cured Hardness (Shore D) | ASTM *** | 85 – 95 | X | X |

| Dielectric Strength V/mil @ 25C | ASTM *** | > 375 | X | |

| Volume Resistivity@ 25°C | ASTM *** | > 1013 | X | |

Cure refer to Section (5).

7) Packaging Requirements

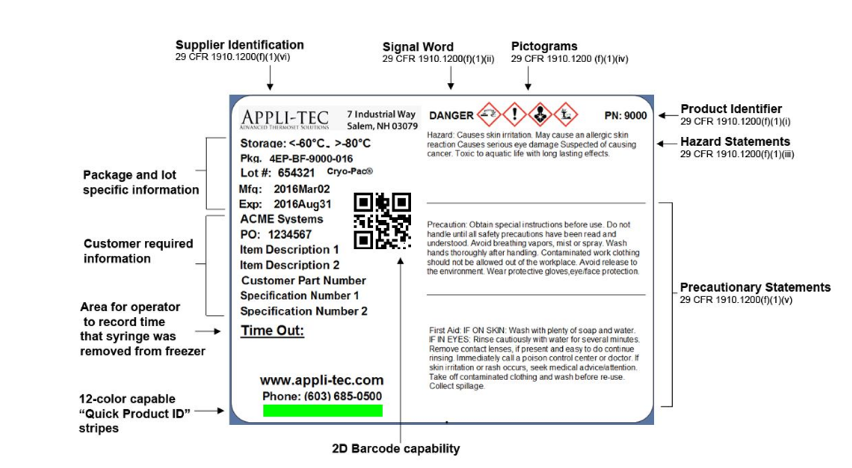

Labels on syringes

Every label has a product identifier, signal word, pictograms and hazard/precautionary statements according the GHS system (Globally Harmonized Standard). The specification should require all packaging must meet current local and regional standards. The package and lot specific information is typically included. Additional customer required information should be included on the specification. Consider adding color codes to your products which may help to quickly identify materials in your freezers when multiple materials are used. The 2D barcode option may save record keeping time and reduce recording errors. Below is an example of how your label will be set-up.

Outer Packaging

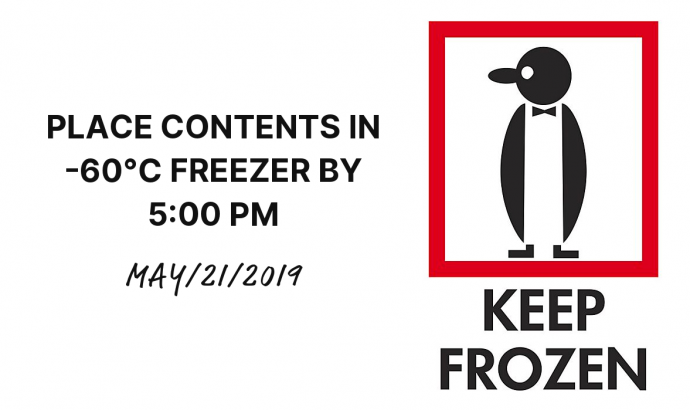

Insulated container containing dry ice with indicator tube ensuring product has remained below -40 °C.

Markings that container must be placed in a -40°C or -60°C freezer by indicated time and date.

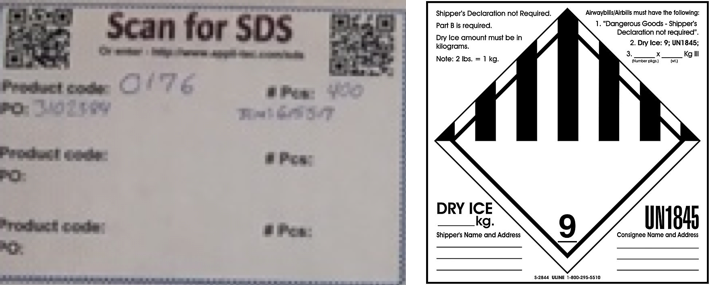

Outer box shall be labeled with the product identifier, number of packages in the box, and required DOT/IATA shipping labels.

Appli-Tec would be happy to assist you with your specification needs.

New Applications

I want to discuss my application challenges, order samples, or place a first-time order.

Existing Applications

I need to reorder an existing part number, I have a BOM/Spec.